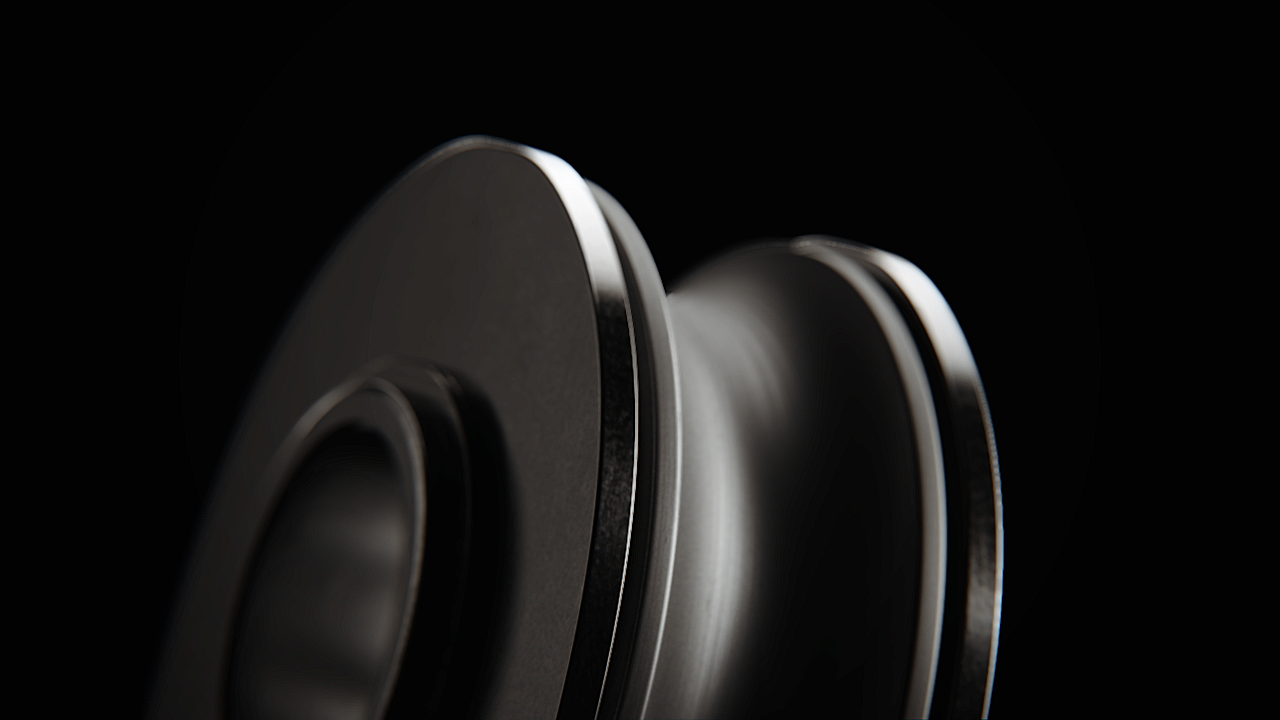

The Making of ZERO leash ring

We made a short movie about the making of ZERO rings: the two hour long machining process presented in 3 minutes.

The way ZERO is designed to distribute the load is allowing it to be more compact. For additional safety it is forged from a solid block of high-strength stainless steel, which makes it extremely durable and bomb-proof and still lighter than many other steel rings on the market.

The main function of this new concept is to shape and support the loop of the leash, and protect both the webbing and the leash rope from abrasion damage.

The leash rope fits into the U-shaped channel of the ring in order to avoid direct contact with the webbing. Compared to other rings, ZERO’s contact area with the webbing is much bigger which means that the forces are equally distributed on the webbing.

When the leash rope is not exposed to additional tension, the accessory cord keeps it secured in its place. In a fall situation the additional tension tightens the rope around the ring, therefore keeping it firm without any chance of slipping away.